MP-Series

Fully/Semi Automatic Stretch Blow Moulding Machine

MP-Series is the latest fully/semi automatic stretch blow moulding machine series which is very flexible for a wide product range. It is specially designed for PET/PP Bottles with volume up to 20L. Machine models in 1-cavity to 4-cavity are possible according to different productivity requirements.

Both the preform heating and bottle blowing processes are combined into the same machine. There are also optional items available for additional order (including the automatic preform feeder and bottle ejection) to become a fully automatic machine.

PET Bottles Application

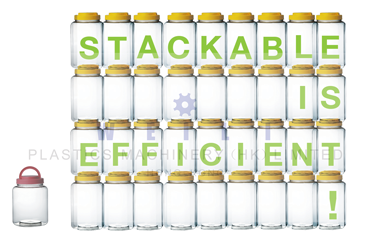

Many brand owners have realized that stackable is not only an idea for storage & transport convenience, but it also provides a sense of strong visual impact and playful incentive to consumers. With strong R&D support from WEI LI, its customers have successfully developed many festival packaging containers with the stackable concept to increase the marketability of their products!

PP Bottle Application

WEI LI has assisted customers to develop a PP hot-fill bottle in their reheat stretch blow moulding machine for beverage bottle to replace the old PP bottle moulded in extrusion blow moulding machine.

WEILI has started helping customers shifting their baby feeding bottles production from PC to PP since 2001. Since many countries has banned the use of baby feeding bottles containing BPA, PP has become the best alternative.

Due to the recyclable and reusable features of PP material, PP sports bottle is appealing to the Eco-Friendly market. Bottle clarity & quality have been much improved improved by using 2-stage stretch blow moulding!

| MP Series-PET | STANDARD | STANDARD-II | STANDARD-IV | MEDIUM | MEDIUM-II | LARGE | LARGE-II | EX-WIDE |

| Volume | 0.8 ~ 1.5L | ≤1L | ≤1L | 1.5 ~ 2.5L | ≤1.5L | 2.5 ~ 5L | 1.5 ~5L | 5 ~ 10L |

| Max. Body Diameter | 90mm | 80mm | 80mm | 130mm | 90mm | 170mm | 170mm | 250mm |

| Max. Neck Diameter | 45mm | 45mm | 45mm | 45mm | 45mm | 45mm | 45mm | 50mm |

| Max. Height | 270mm | 230mm | 250mm | 270mm | 280mm | 330mm | 330mm | 380mm |

| Average Power Consumption* | 6~12KW | 9~15KW | 16~18KW | 9~15KW | 9~15KW | 9~15KW | 15~20KW | 15~20KW |

| Production Capacity(BPH)** | 800 ~ 1,000 | 1,200 ~ 1,500 | 2,800 ~ 3,000 | 500 ~ 800 | 1,000 ~ 1,300 | 500 ~ 800 | 1,000 ~ 1,200 | 500 ~ 600 |

| No. of Mould Cavity | 1 | 2 | 4 | 1 | 2 | 1 | 2 | 1 |

* Average power consumption depends on resin grade & bottle wall-thickness.

** It depends on the preform design, preform thickness, bottle design and quality of PET resin.